Let the Fermentation Begin!

In the last blog I left off as the tanks were filling with juice or crushed grapes and getting ready to change into that wonderful liquid we call wine. Don’t hold your breath though because it will be a long time before this must turns into something you can find in a wine glass at the tasting room.

Now before I even go into what happens next in this crazy process, I have to say that every winery has its own way of proceeding. The basic process of turning juice to wine is the same, but each winemaker has their own special additions, techniques and in some rare cases secret rituals to mold the wine into something incredible. I will explain how we do it here at Castoro, the correct way, haha, just kidding. All shots are called by our super star winemaker Tom Myers and followed precisely by his sidekicks all over the cellar. Think of it like Batman with a whole bunch of Robins running around fighting the crime that is unfinished and undrinkable wine.

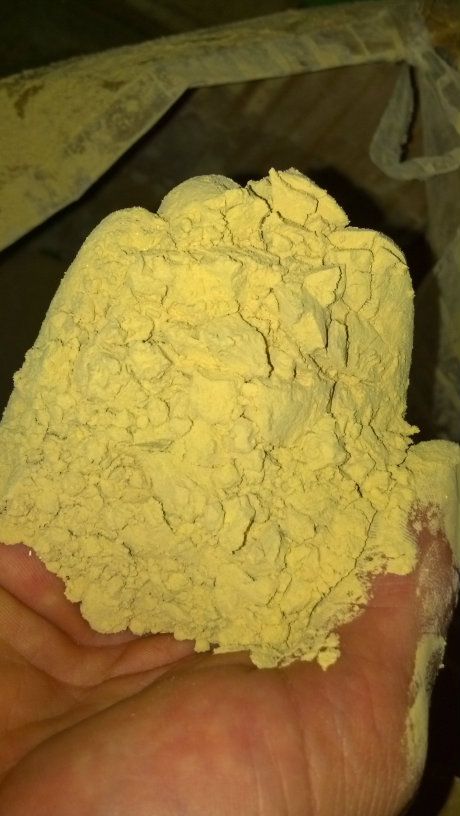

The first decision Tom makes is which type of yeast to add to the must or juice. Yeast has about as many variations as there are grapes in the Paso Robles AVA. It can be anything from wild natural yeast to something mass-produced on a farm in France or Germany. When added, in the absence of oxygen and with the correct nutrients, the yeast will begin to eat the sugars in the juice, converting them to alcohol, CO2, and lees or sediment. The juice can be fermented till it is dry and no more sugar remains, or the process can be stopped to keep some residual sugar and create a sweeter wine such as our splendid Muscat Canelli. The higher the sugar content at the beginning the higher the possible alcohol percentage will be and Paso is known for its strong wines. In order to make sure those little living yeast organisms are healthy and performing at their highest level, yeast aid or nutrients are added as well. I attached some pictures of the yeast as well as the more powdery substance, which is the yeast aid. I could write a novel about yeast so I’m leaving you with that brief description and hopefully enough interest to read a little more into the fermenting process yourself.

For the production of red wine, the grape skins and seeds are still mixed with the juice while the yeast and aide are added. However, like ice the skins and seeds slowly float to the top and separate from the liquid. In order to mix the whole batch up, keep it uniform and prevent a hard crust of skins from forming at the top, the cellar boys use a technique known as a pump-over. This involves sucking the juice out of the bottom of a tank and pumping it through a hose back into the top to evenly disperse it over the skins. Pump-over times vary, but on average it is done for about 30 minutes twice a day until the fermentation process is complete. Below is a picture of Wes and Jim, managing the multiple pump-overs they just started after lunch. Red wine is fermented with the skins in order to extract the maximum amount of flavor and color for the end product.

Grape Update! The weather has been near perfect and that means ripe, juicy grapes, deep in color and high in sugar. Merlot, Syrah, Petite Sirah and Cabernet Sauvignon grapes continue to flow in and we are finally seeing the first of our Zinfandel grapes go into the tanks. The best of the Zin is still to come, however, from our CCOF certified organic Whale Rock and Cobble Creek Vineyards. Both are located on the west side of Paso Robles. Our Whale Rock Vineyard has already produced a magnificent batch of Pinot Noir, riper and more flavorful than ever before. This wine will be sure to knock your taste buds back to life. We also received some Malbec grapes from our Hog Canyon Vineyard, which have, as Tom describes, a great mouth feel, rich tannins and ripe flavors.

That’s all for now, but I’ll be back before you can say “Saccharomyces cerevisiae” (One of the most common forms of yeast used in winemaking).

Thanks for reading,

Erik